BoatKoat Laminates

BKL Anti-fouling Coating Accessories

Over the years, we have learned several tricks that help with the application of our BKL anti-fouling coating / film.

Helpful Options

No Returns

Teflon coated film

Teflon coated film 16-inchs wide by the required length requested: In many cases, straps used for lifting a vessel are rough, and at times, boats are not centered in the straps during launch causing the vessel to shift as it is floated. The Teflon surface against the straps allows slippage without damaging the applied laminate. Placement of the Teflon film should mirror the pressure point locations of straps.

Pressure cutter

1-1/2-inch pressure cutter (various brands): We recommend using a pressure cutter when necessary to adjust the size of applied BKL laminate. A razor blade will easily scar gelcoat, aluminum, and nylon/vinyl surfaces. Please note that a pressure cutter can mar surfaces as well if too much weight is applied.

Rubber Roller

This roller is easy to maneuver and handle while applying the BKL laminate. A 20-pound pressure using a rubber roller helps to push the adhesive into surface irregularities.

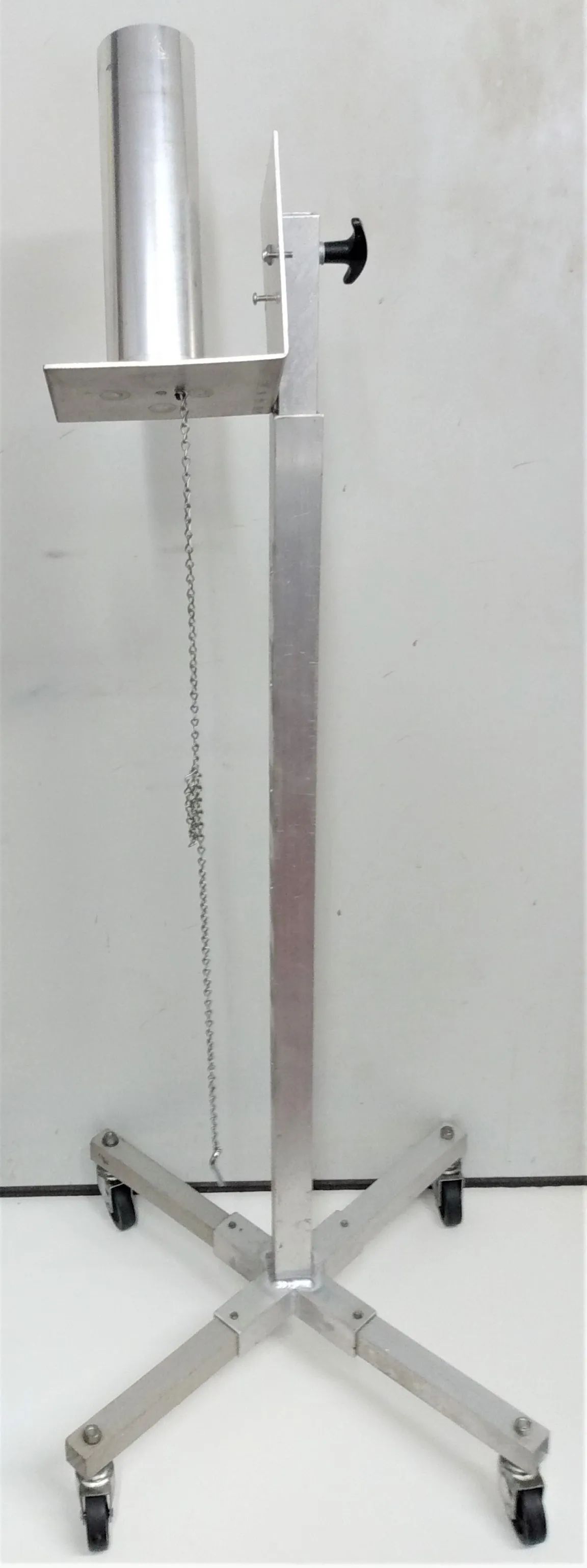

Adjustable roll holder

Our roll holder allows the BKL product to be held in place while lengths of material are measured and cut to desired lengths. The holder adjusts to the angle and height necessary, which aides with laminate handling and application. The BKL roll holder is an aluminum product and will not rust. This tool is most applicable for marinas that provide bottom coating services.

.jpeg?fit=outside&w=1600&h=3176)

One trick is to apply just a bit of liquid silicone to the cutting edges of scissors. Allow the silicone to dry before cutting the laminate. This little trick allows the scissors to cut through the laminate without sticking to the adhesive. Several applications of the silicone will be necessary during the laminate application process. The silicone does wear off the scissors.

Please contact us for current prices and availability.